Winding Belts

High-Performance Winding Belts for Continuous Production

General Information

We supply high-precision winding belts tailored for the paper and cardboard tube industry. These belts serve as the critical link between your machine and the final product, ensuring smooth, consistent winding performance. We offer both original and compatible belts with endless, connectionless construction and woven edges to prevent fraying and maximize belt life.

Our belts are manufactured with polyester or aramid fabrics and customized coatings such as PVC to ensure high grip, flexibility, and resistance to heat, abrasion, and chemicals. Each belt is precisely engineered to fit the winding geometry and surface requirements of your application.

Common Applications

- Paper tube winding machines

- Cardboard tube manufacturing

- Industrial spiral winding lines

- Packaging and converting systems

Key Features

- Endless and connectionless design with no breaking points

- Woven-edge construction to prevent fraying

- Custom fabric and coating combinations for specific applications

- High flexibility for small roller diameters

- Excellent grip and abrasion resistance

- Temperature resistance from -10°C to +80°C

- Non-directional running behavior

- Resistant to adhesives, oils, and greases

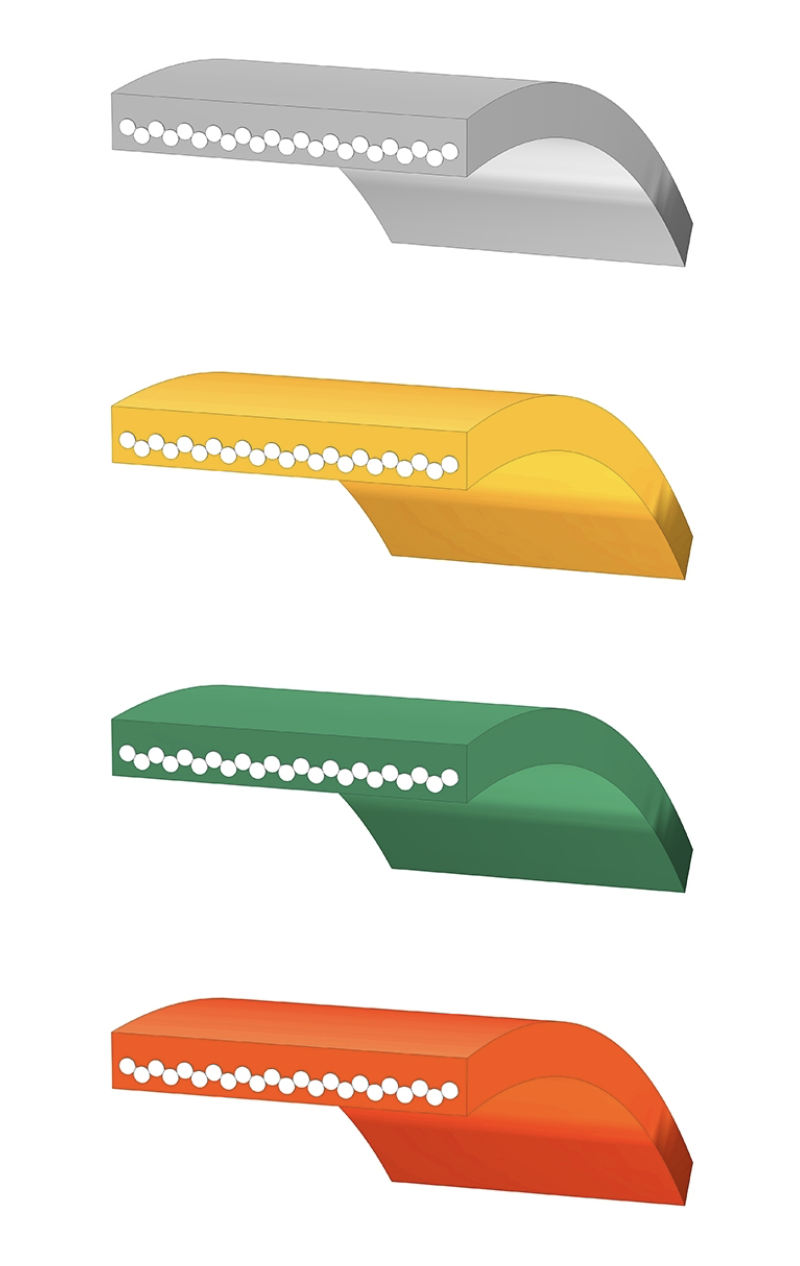

Fabric Options

- Polyester:

- 2–3 mm thickness → 125 kg/cm belt width

- 4–5 mm thickness → 250 kg/cm belt width

- 6–8 mm thickness → 375 kg/cm belt width

- Aramid: 500 kg/cm belt width

Coating Options

- PVC coating with Shore-A hardness from 35 to 90

- High abrasion resistance and grip properties

- Homogeneous coating without adhesives or binders

- Custom constructions available

Ordering Support

We support custom winding belt sizing and selection. Belt length is calculated using the formula: (2xe)+d+f, where:

- e = average distance between axles

- d = circumference of the drum

- f = circumference of the tube

The belt width should be 5–7 mm narrower than the final paper web (e.g., for 125 mm paper web, use 120 mm belt).

Worldwide Shipping & Availability

All winding belts are available with worldwide shipping. Whether for OEM integration or replacement, we ensure quick delivery and expert support to optimize your production line.

Request a quote or contact our technical team for assistance.