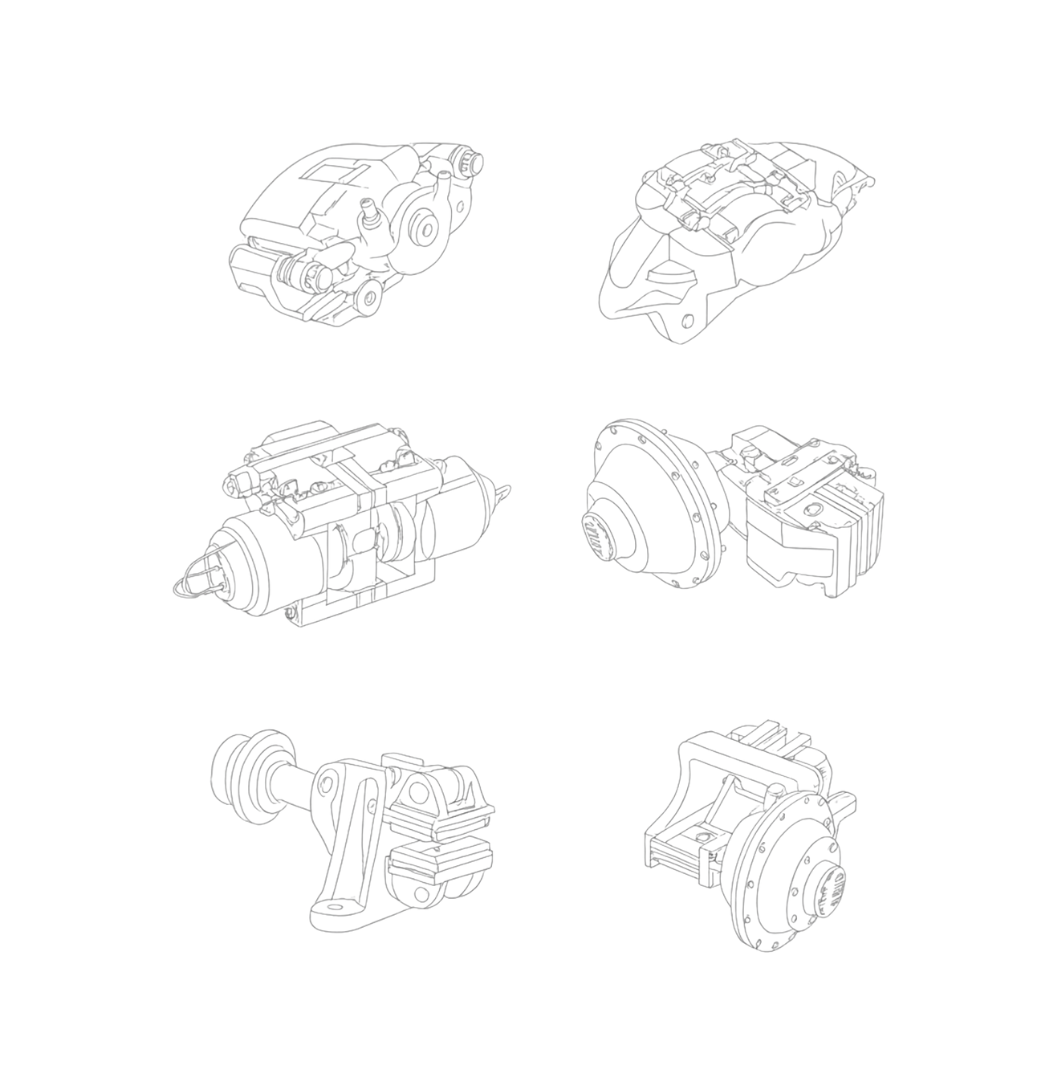

Caliper Brakes

Industrial Brake Systems for Safety, Holding, and Dynamic Braking

General Information

We supply a comprehensive range of industrial caliper brakes, available in floating, fixed, hydraulic, pneumatic, manual, and spring-applied (safety brake) configurations. Our selection includes both original and compatible units from top global manufacturers and engineered to ensure high-performance braking in demanding applications.

Caliper brakes are designed to provide reliable clamping force over rotating discs, enabling controlled deceleration, emergency stops, or static holding. Depending on the actuation method, they can operate via hydraulic or pneumatic pressure, manual lever mechanisms, or automatic spring engagement for fail-safe applications. Suitable for both dynamic and static braking, these systems are critical in environments requiring safety, precision, and repeatability.

We offer single-acting and dual-acting variants, with options for high-temperature resistance, corrosion protection, and wear monitoring systems. Whether you need a retrofit for an existing setup or a brake solution for new equipment, our range covers multiple torque capacities, mounting interfaces, and disc thicknesses. All models are available with worldwide shipping and backed by expert technical support.

Common Applications

- Industrial disc braking systems

- Mining and conveyor systems

- Wind turbines and energy systems

- Material handling equipment

- Wire and cable processing machinery

- Elevators and hoisting equipment

- Test benches and rotating platforms

- Automated safety systems in robotics

Key Features

- Available as floating, fixed, hydraulic, pneumatic, manual, or spring-applied brakes

- Designed for high torque capacity and precise control

- Options for static holding or dynamic braking

- Manual release or auto-reset for safety-critical applications

- High wear resistance and long service intervals

- Suitable for harsh environments with dust, moisture, or vibration

- Mounting options: side-mounted, top-mounted, or customized interfaces

Ordering Support

Our technical team can assist with torque calculations, disc compatibility, mounting arrangements, and actuation preferences. Whether you’re replacing a caliper brake from a discontinued model or engineering a new solution, we provide full documentation, dimensional verification, and support for OEM replacement or retrofit integration.

Worldwide Shipping & Availability

All caliper brake models are available for international delivery, with scalable logistics to support plant upgrades or urgent service needs. From spring-applied safety brakes to high-performance hydraulic calipers, we ensure fast lead times and consistent availability.

Request a quote or contact our technical specialists to identify the ideal braking system for your machinery.