Reverse Engineering

Precision-Engineered Solutions for Obsolete and Hard-to-Find Components

General Information

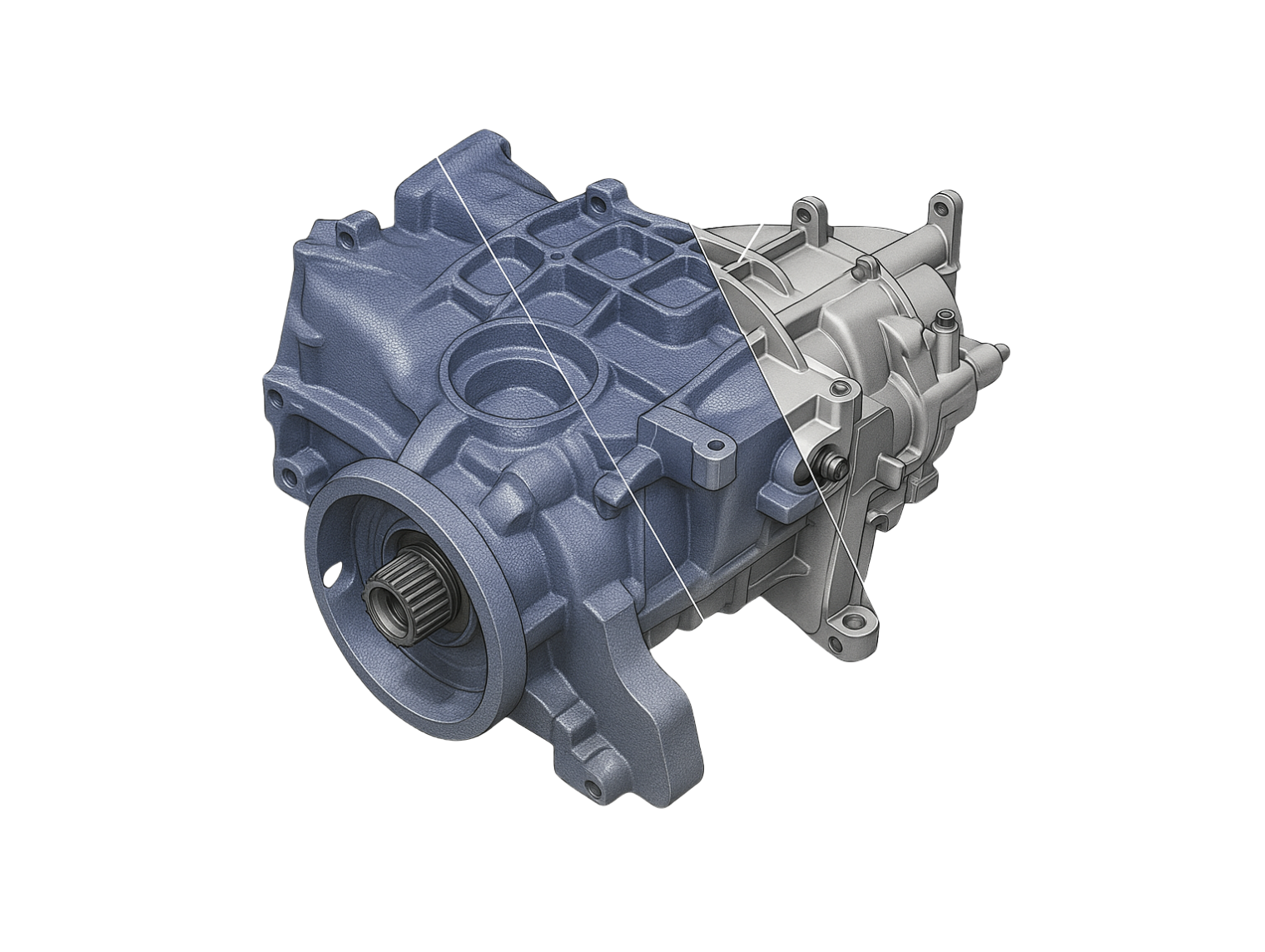

Our Reverse Engineering services allow us to reproduce and enhance critical industrial spare parts when original components are no longer available, have long lead times, or require performance improvements. Using advanced 3D scanning, CAD modeling, and material analysis, we can develop customized spare parts that are fully compatible with existing machinery and production lines.

Reverse engineering enables accurate replication of OEM dimensions and functional characteristics, while also offering opportunities to upgrade materials, coatings, and tolerances for extended service life. All customized components are delivered with full technical documentation and are available with worldwide shipping.

Our expertise covers simple mechanical elements to complex assemblies, ensuring precise fit, reliability, and optimized performance for demanding industrial environments. Whether for one-off replacements or recurring production, reverse-engineered parts provide a secure and cost-effective solution.

Common Applications

- Obsolete or discontinued spare parts reproduction

- Critical machinery components with long OEM delivery times

- Customized upgrades for improved wear resistance and durability

- Replicating parts with dimensional modifications for new setups

- Reverse-engineering broken or worn parts without available drawings

- Redesign for cost reduction while maintaining OEM performance

- Parts for mining, construction, energy, and heavy-duty machinery

- Special components for automation and robotic systems

Key Features

- High-precision 3D scanning and CAD modeling for exact replication

- Material analysis and selection: carbon steel, stainless steel, alloys, polymers

- Dimensional accuracy within industrial tolerance standards

- Capability to enhance designs with improved coatings or heat treatments

- Shorter lead times compared to OEM supply chains

- Documentation support including 3D CAD files, drawings, and inspection reports

- Compatibility validation with OEM specifications and machinery fit

Ordering Support

Our engineering team provides full assistance in evaluating worn or broken parts, creating accurate models, and validating compatibility with your equipment. We support cross-referencing with OEM part numbers, material certifications, and tolerance checks to ensure seamless integration.

Worldwide Shipping & Availability

All customized and reverse-engineered products are available for global shipping with reliable logistics. From single prototype development to full batch production, we ensure consistent quality, fast turnaround, and secure packaging. Request a quote or contact our technical team to evaluate your part and develop the optimal solution for your application.