Technical Equipment

Custom Industrial Machinery for Wire & Cable Manufacturing

At ACOTEQ, all machinery is engineered and manufactured according to your specific production requirements. Our engineering approach ensures that each machine matches the way your factory actually works, not the other way around.

Whether you need to modernize a single process or build an entirely new production line, we design and develop custom machinery that adapts to your operational realities, integrates smoothly with existing equipment, and supports your growth objectives with reliable, long-term performance.

OUR ENGINEERING WORKFLOW

Every machine we build follows a structured engineering workflow to guarantee technical accuracy and predictable performance.

Our development process includes:

- Technical assessment of your process and product requirements

- Mechanical design tailored to your factory layout

- Component selection based on performance, durability, and maintainability

- Prototyping and validation through in-house engineering reviews

- Manufacturing under controlled quality standards

- Integration with upstream and downstream equipment

- On-site installation, commissioning, and operator training

This methodology allows us to deliver custom industrial machinery that aligns with your production strategy, improves line efficiency, and ensures long-term operational stability.

WHY OUR CUSTOMERS TRUST US

We focus on delivering engineering-first solutions built for the technical demands of the wire & cable industry. Each project is evaluated through a complete development process that considers every factor influencing productivity, quality, maintenance, and lifecycle cost.

Key design parameters we evaluate:

- Production capacity: output, speed, throughput

- Material characteristics

- Available floor space & layout

- Budget & scalability

- Mechanical, electrical & automation integration with existing lines

From concept to commissioning, we support the full project lifecycle, including engineering design, equipment manufacturing, factory acceptance testing, installation, line integration, commissioning, and training of your operational teams. Our involvement ensures that each machine performs seamlessly within your existing production ecosystem from day one.

TYPES OF MACHINES WE CAN SUPPLY

We develop a complete range of custom-engineered machinery for wire and cable manufacturing. Each solution is built to increase productivity, improve process stability, and integrate smoothly with your existing production lines. Our capabilities cover the entire manufacturing chain ensuring fully aligned and long-term operational performance.

We engineer custom wire drawing solutions designed for stable reduction ratios, high-speed performance, and smooth integration with upstream and downstream equipment.

Drawing machines we can supply:

- Rod breakdown lines

- Single-wire drawing lines

- Multi-wire drawing lines

- Equipment used for drawing

For dies, bearings, lubricants, filtration units, and more, visit: Spare & Wear Parts.

If you would like a quotation or technical assessment, feel free to reach out through our contact form.

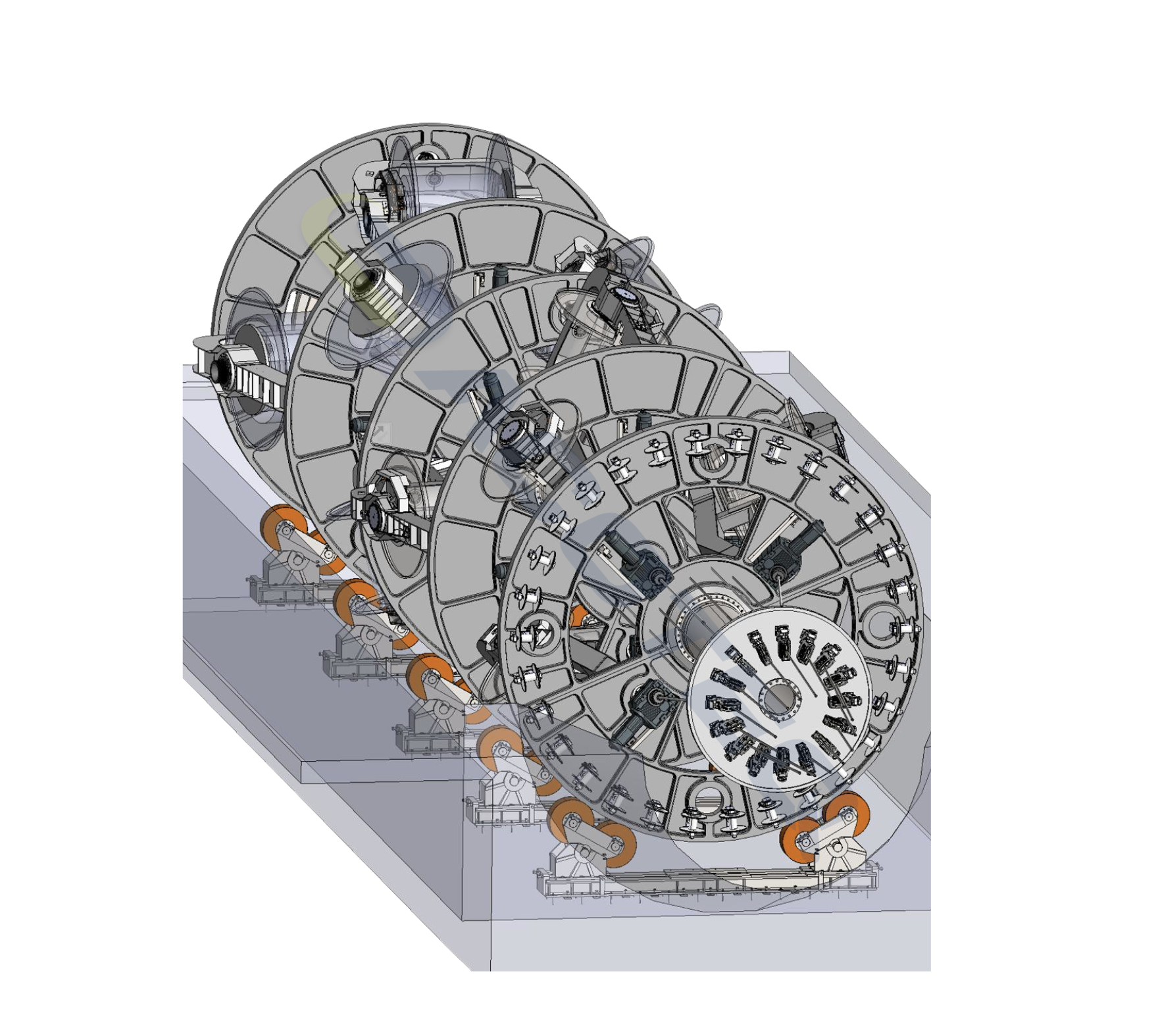

We design stranding and cabling machinery built for conductor stability, controlled lay-length, and precise tension behavior across all cable types.

We supply the following stranding machines:

- Single-twist and double-twist machines

- Bar strander

- Skip strander

- Bow strander

- Planetary strander

- Drum twister

For bows, rotating components, pulleys, bearings, pay-off parts, and more, visit: Spare & Wear Parts.

If you would like a quotation or technical assessment, feel free to reach out through our contact form.

Our extrusion lines are engineered for dimensional accuracy, polymer stability, and consistent insulation or sheathing performance.

We offer a full range of extrusion configurations:

- Extruders from 45mm 24D to 200mm 30D

- Equipment used in extrusion lines

For screws, barrels, crossheads, tips, dies, heaters, cooling elements, and more, visit: Spare & Wear Parts.

If you would like a quotation or technical assessment, feel free to reach out through our contact form.

We build taping and armouring equipment designed for uniform wrapping, stable tension control, and compatibility with different reinforcement materials.

Our taping and armouring capabilities include:

- Foil, steel, and net taping heads

- Armouring machines for copper, aluminum, steel wire, or Kevlar

For taping heads, tensioners, bearings, consumables, and more, visit: Spare & Wear Parts.

If you would like a quotation or technical assessment, feel free to reach out through our contact form.

We supply standalone units engineered to upgrade existing lines or support modular plant expansion.

Available machine units include:

- Pay-offs

- Take-ups

- Single and double spoolers

- Belt-type capstans

- and more

For replacement components, upgrades, and more, visit: Spare & Wear Parts.

If you would like a quotation or technical assessment, feel free to reach out through our contact form.

We develop coiling and packaging systems built for clean coil formation, stable tension, and efficient end-of-line handling.

We can supply:

- Coiling machines

- Packaging machines

For guides, rollers, packaging-related parts, and more, visit: Spare & Wear Parts.

If you would like a quotation or technical assessment, feel free to reach out through our contact form.