Engineering Phase Support

Precision Design, Calculation, and Technical Solutions to Maximize Roller Performance

Precision is not just a requirement; it is the baseline of our engineering philosophy. At ACOTEQ, our Engineering Phase Support ensures that every roller is not merely a spare part, but a calculated component optimized for your specific machinery. We bridge the gap between theoretical physics and real-world application, guaranteeing efficiency, structural integrity, and operational safety.

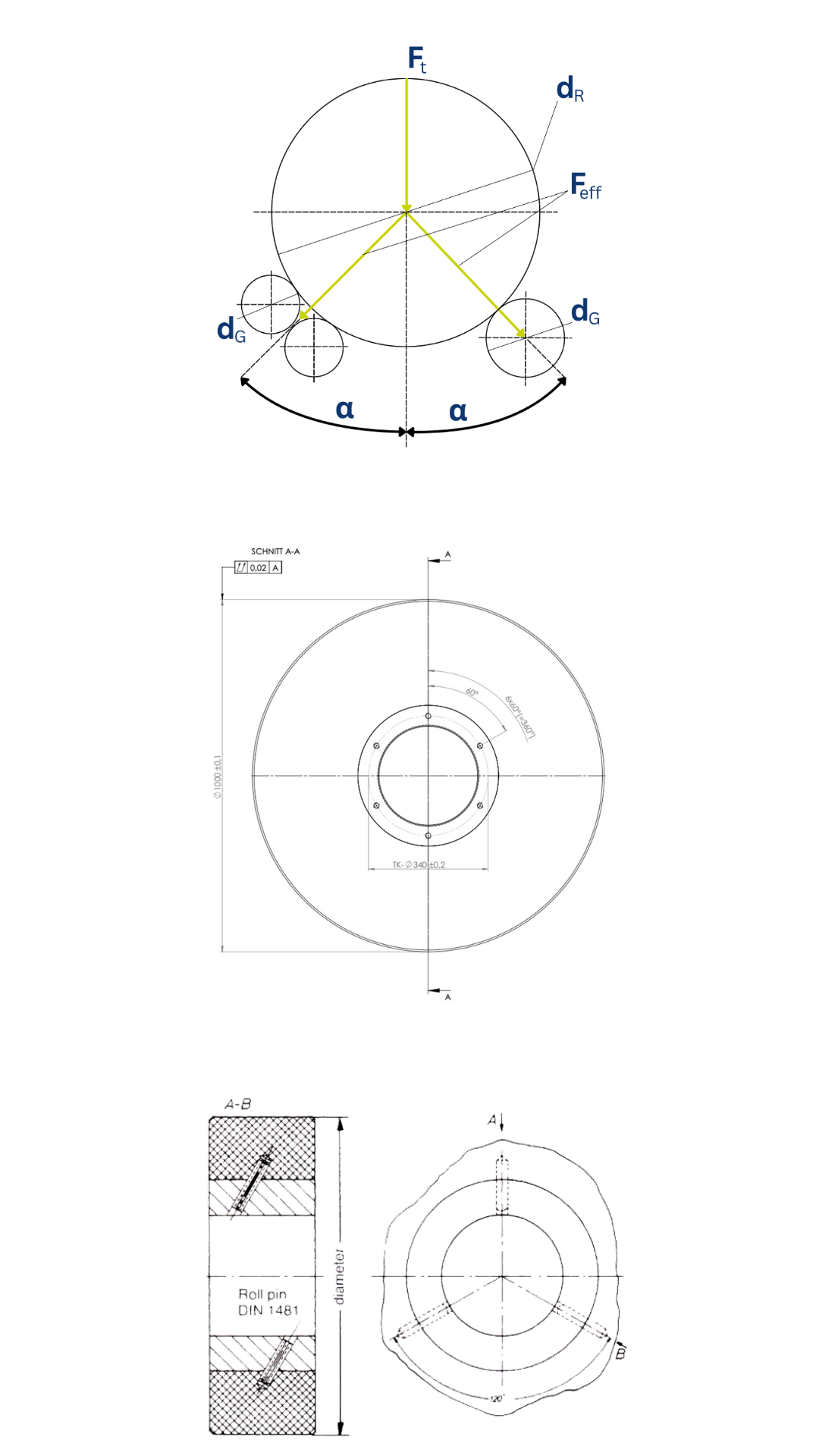

Physics-Driven Calculation & Design

A high-performance roller starts with rigorous mathematical analysis. We move beyond standard charts to analyze your specific application constraints, considering operational speeds, belt tension, and thermal conditions. Our process determines:

- Optimized Geometry: Calculation of ideal roller diameter and width to handle specific stress loads and ensure uniform distribution.

- Safety Factor Verification: We engineer a safety margin that ensures reliable performance even under fluctuating loads or extreme peak conditions.

- Failure Prevention: By combining advanced load simulation with operational data, we minimize the risk of premature fatigue, deflection, or vibration.

Technical Engineering & Integration

Once parameters are defined, we transform concepts into actionable, manufacturing-ready technical data. This phase ensures that the roller fits seamlessly into your existing assembly:

- 3D CAD Modeling: Detailed modeling of hubs, bores, and interference fits to ensure precise integration.

- Surface Topology: Optimization of surface finish and contact geometry to maximize friction coefficients while minimizing wear on the strip.

- Runout Control: Strict tolerance definition to prevent Total Indicated Runout (TIR), ensuring stability at high rotational speeds.

- Production Documentation: Comprehensive manufacturing drawings and quality specs ready for immediate production and inspection.

Technical Selection of Bearing Systems

The bearing is the critical failure point of any rotating assembly. We provide a design to maximize the life of your system:

- Load Capacity Analysis: Calculation of dynamic and static load ratings to select the optimal bearing series.

- Type Selection: Strategic selection of ball, spherical roller, or plain bearings based on speed and load direction.

- Sealing & Lubrication: Specification of sealing concepts (labyrinth/contact) and lubrication regimes to prevent contamination and overheating.

- Maintenance Prediction: Service life calculations that allow for predictive maintenance planning rather than reactive repairs.

Design of Roller Supports

A roller is only as stable as its support. We engineer housing and support structures designed for rigidity and ease of access:

- Structural Rigidity: Supports engineered to withstand static and dynamic forces without deformation or resonance.

- Precision Alignment: Integrated adjustment features that ensure perfect parallelism and belt tracking.

- Material Durability: Selection of corrosion-resistant materials capable of withstanding harsh industrial environments.

- Maintenance-Friendly Design: Quick-change concepts that simplify inspection and replacement, drastically reducing line downtime.

Development of Complete Under-Roller Units

For complex applications, we design integrated under-roller assemblies that function as turnkey solutions:

- Vibration Isolation: Designs focused on structural stability to minimize operational inconsistencies and chatter marks.

- Accessibility: Simplified layouts for easy cleaning, inspection, and fine-tuning.

- Modularity: Adaptable designs compatible with various machine footprints, offering flexibility across different production lines.

Why Trust ACOTEQ Engineering?

- Grounded in Physics: We don’t guess; we calculate based on industry standards and mechanical principles.

- Custom-Fit Solutions: Every design is tailored to your specific machine geometry and production goals.

- Predictive Reliability: We design for longevity, reducing unplanned stops and maintenance costs.

- End-to-End Responsibility: We support you from the initial calculation through to the final technical documentation.