Technical Assistance

On-Site Support, Lubrication Optimization, and Roller Upgrades for Maximum Performance and Reliability

At ACOTEQ, we go beyond supply to ensure lifecycle performance. We provide comprehensive technical assistance designed to maximize the ROI of your industrial rollers. Through expert on-site diagnostics, maintenance strategies, and modernization services, we extend component life, improve operational efficiency, and drastically reduce unplanned downtime.

On-Site Engineering Support

Our specialized engineers travel to your facility to perform deep-dive diagnostics and optimization. We focus on the critical parameters that define roller performance:

- Surface Integrity Analysis: We inspect running surfaces to detect early signs of wear, ensuring smooth interaction between the roller and the ring or strip.

- Load Condition Verification: We calculate and verify that rollers are subjected to correct mechanical loads (N/mm), preventing over-stressing and uneven wear patterns.

- Precision Alignment: We conduct alignment checks and corrections to ensure stable belt tracking and reliable operation.

- Operational Training & Knowledge Transfer: We educate your maintenance staff on best practices for inspection and operation, empowering your team to prevent unexpected failures.

Lubrication System Optimization

Heat and friction are the primary causes of roller failure. A properly designed lubrication strategy is crucial for thermal management and longevity:

- Customized Lubrication Protocols: We specify exact intervals and application methods (manual or automatic) tailored to your line speed and load.

- Efficiency at Critical Points: We optimize lubrication points to ensure grease or oil reaches the bearing and running surfaces effectively.

- Friction & Heat Reduction: By minimizing mechanical losses, we lower operating temperatures and significantly extend the service life of the roller material.

Modernization of Legacy Rollers

Industrial machinery often outlasts its individual components. Instead of replacing entire units, we offer targeted retrofit solutions to bring your equipment up to modern standards:

- Material Upgrades: We replace outdated steel or Lignostone (laminated densified wood) rollers with high-performance GESADUR® technology.

- Design Optimization: We adapt older components to meet current machine requirements and higher production speeds.

- Maintenance Reduction: Our improved roller designs minimize operational interruptions and simplify routine upkeep.

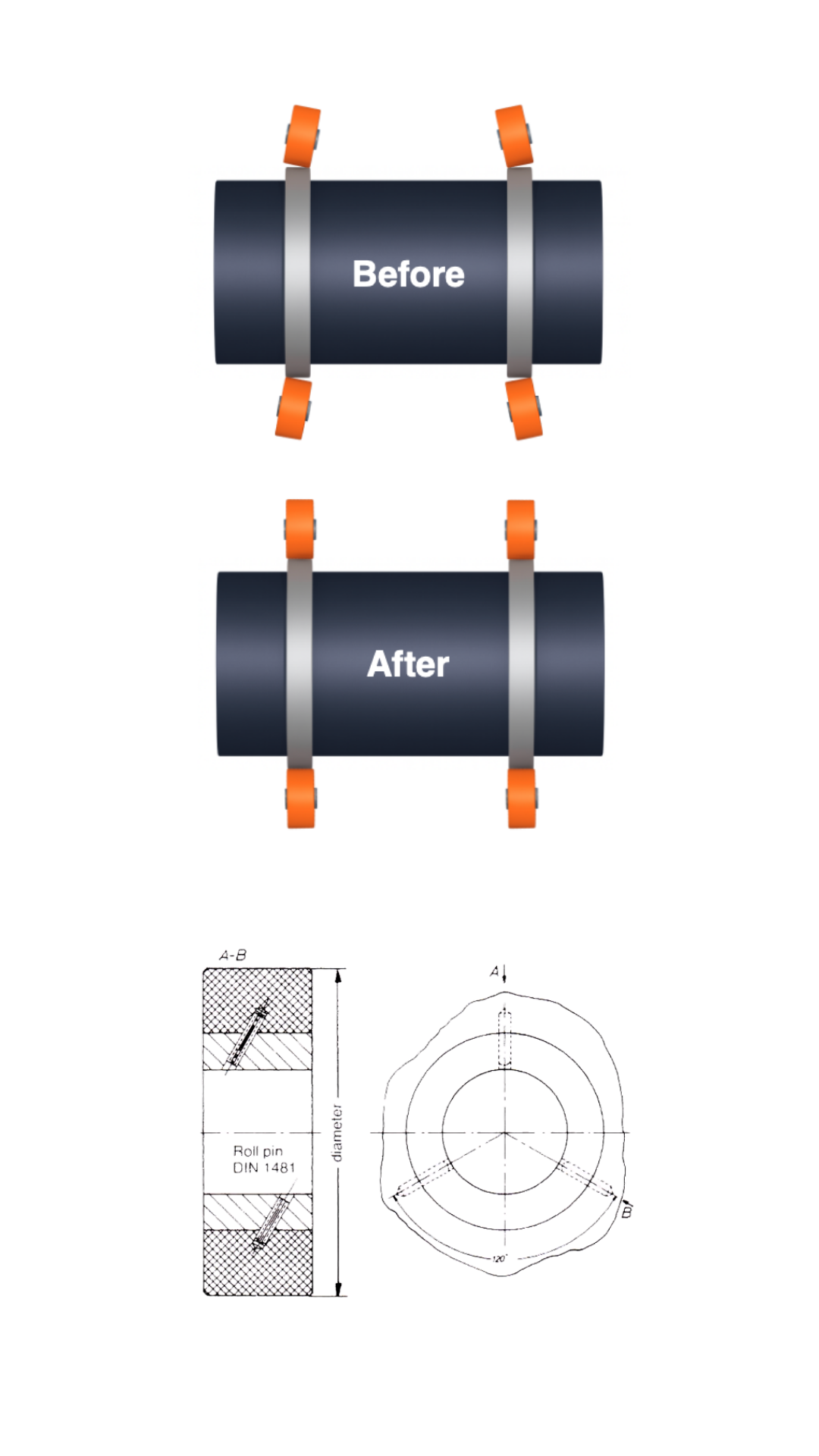

High-Performance Bearing Upgrades

The bearing is the heart of the roller assembly. Our upgrade services ensure your housing systems can handle modern production demands:

- Advanced Bearing Technology: We replace standard units with high-performance bearings offering superior durability and load capacity.

- Load Distribution Optimization: We re-engineer the assembly to improve stability and extend fatigue life.

- Low-Friction Solutions: Implementation of maintenance-free or low-friction bearings to reduce energy consumption and wear.

- Housing Adaptation: We implement advanced bearing solutions that fit your existing housings, avoiding the need for costly structural modifications.

Why Choose ACOTEQ for Technical Assistance?

- Hands-On Expertise: Direct access to engineers who understand the physics of your production line.

- Tailored Engineering: Solutions for lubrication, rollers, and bearings are calculated specifically for your machinery, not generic off-the-shelf fixes.

- Downtime Reduction: Proactive maintenance strategies that keep your line running longer.

- Long-Term Reliability: We focus on structural stability to ensure consistent product quality over time.