GESADUR Rollers

Advanced Engineering, Seamless Logistics, and Expert Technical Assistance to Maximize Roller Performance

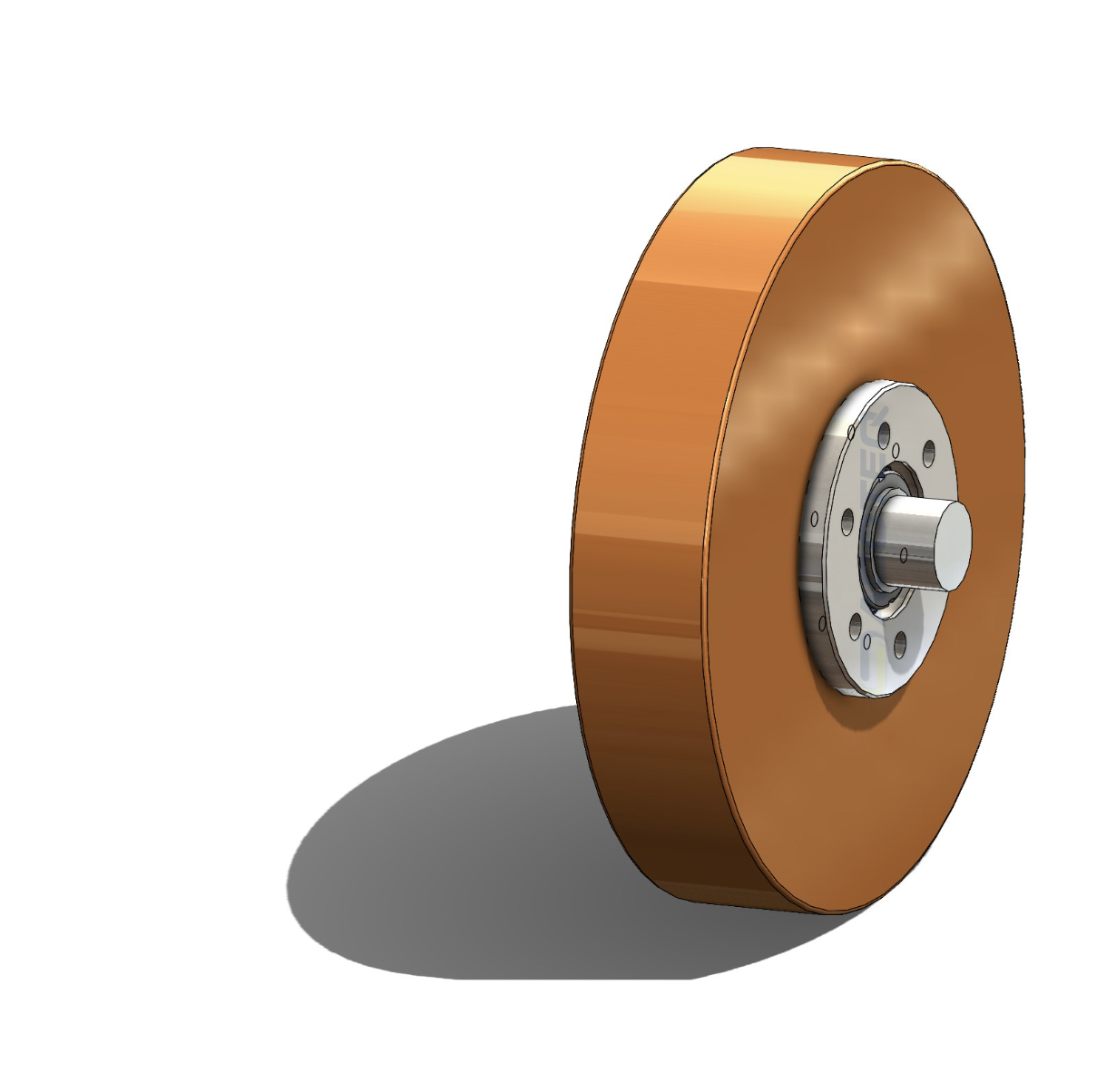

In the high-precision world of metal processing, the margin for error is microscopic. GESADUR® Rollers by Sachsenröder provide the ultimate solution for cold rolling, pickling, and galvanizing lines. Manufactured from a unique, binder-free natural fiber material, these rollers offer a coefficient of friction (µ > 0.5) that rubber and PU cannot match, combined with “self-healing” properties that resist cuts from sharp strip edges.

However, a superior product requires superior support. We provide end-to-end management of your roller systems, ensuring maximum uptime and operational ROI.

Sales & Logistics

We don’t just supply a roller; we deliver a complete system designed for longevity.

- GESADUR® Rollers: The industry standard for tension, bridle, and squeeze rollers. Manufactured from our patented compressed natural material, they feature unique “self-healing” properties against cuts and protect sensitive materials (Stainless Steel, Aluminum, Copper) from marking and damage.

- GESACLEAN: High-performance cleaning roller systems. Designed to effectively remove oils, emulsions, and residual particles from the strip, ensuring a flawless surface before critical processing or rewinding phases.

- Lubrication System: Controlled friction requires thermal management. Our specialized lubrication systems prolong the service life of GESADUR® rollers, preventing overheating and ensuring consistent operability under high workloads.

Engineering Phase Support

Every production line is unique. Our engineering department operates as an extension of your technical team to ensure seamless integration.

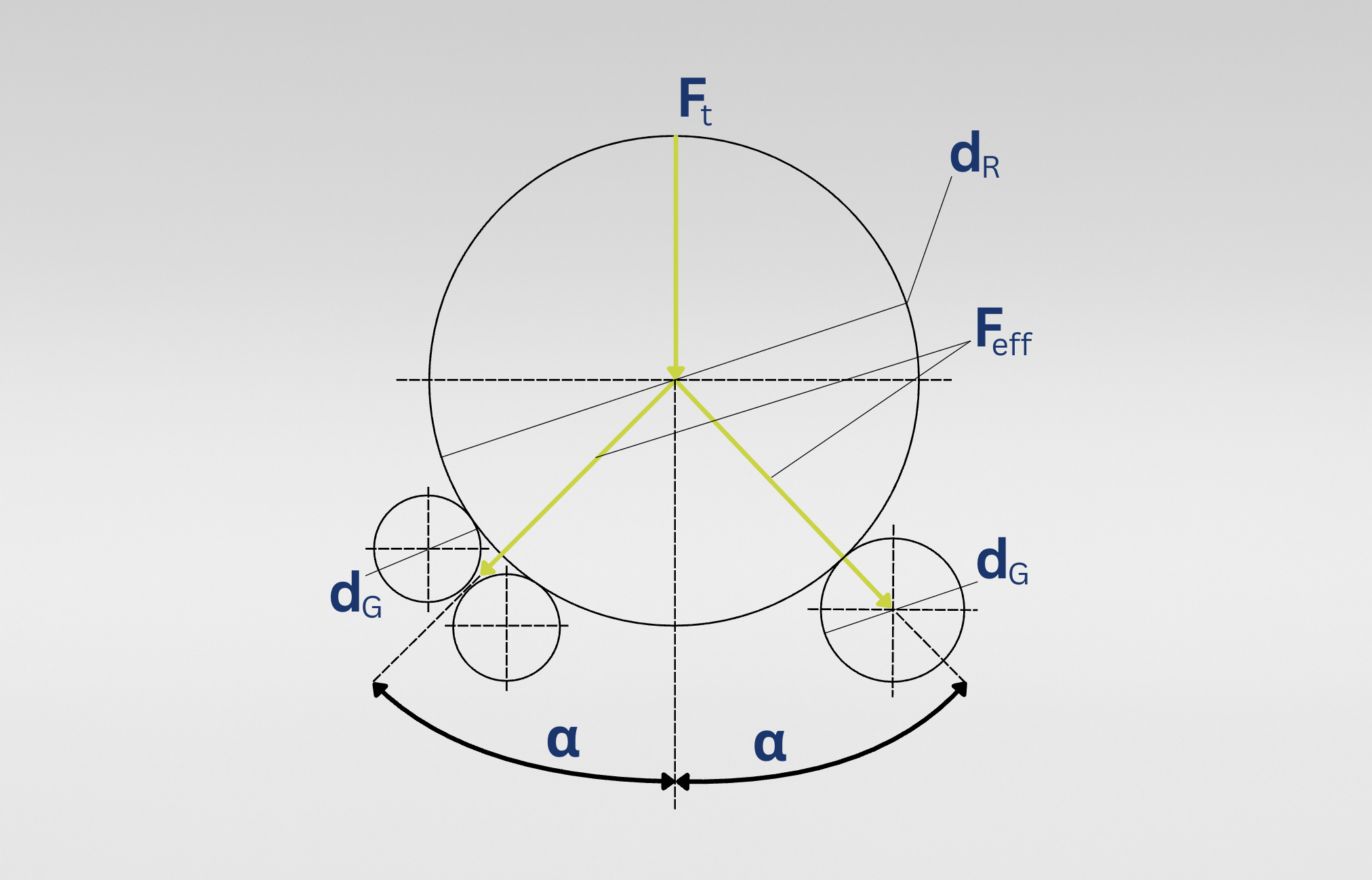

- Calculation & Design: We perform exhaustive linear load (N/mm) calculations and tension simulations to determine the exact hardness and composition of the GESADUR® roller your process requires.

- Technical Engineering: We develop detailed blueprints and technical specifications for roller integration into both new lines (OEM) and existing retrofits.

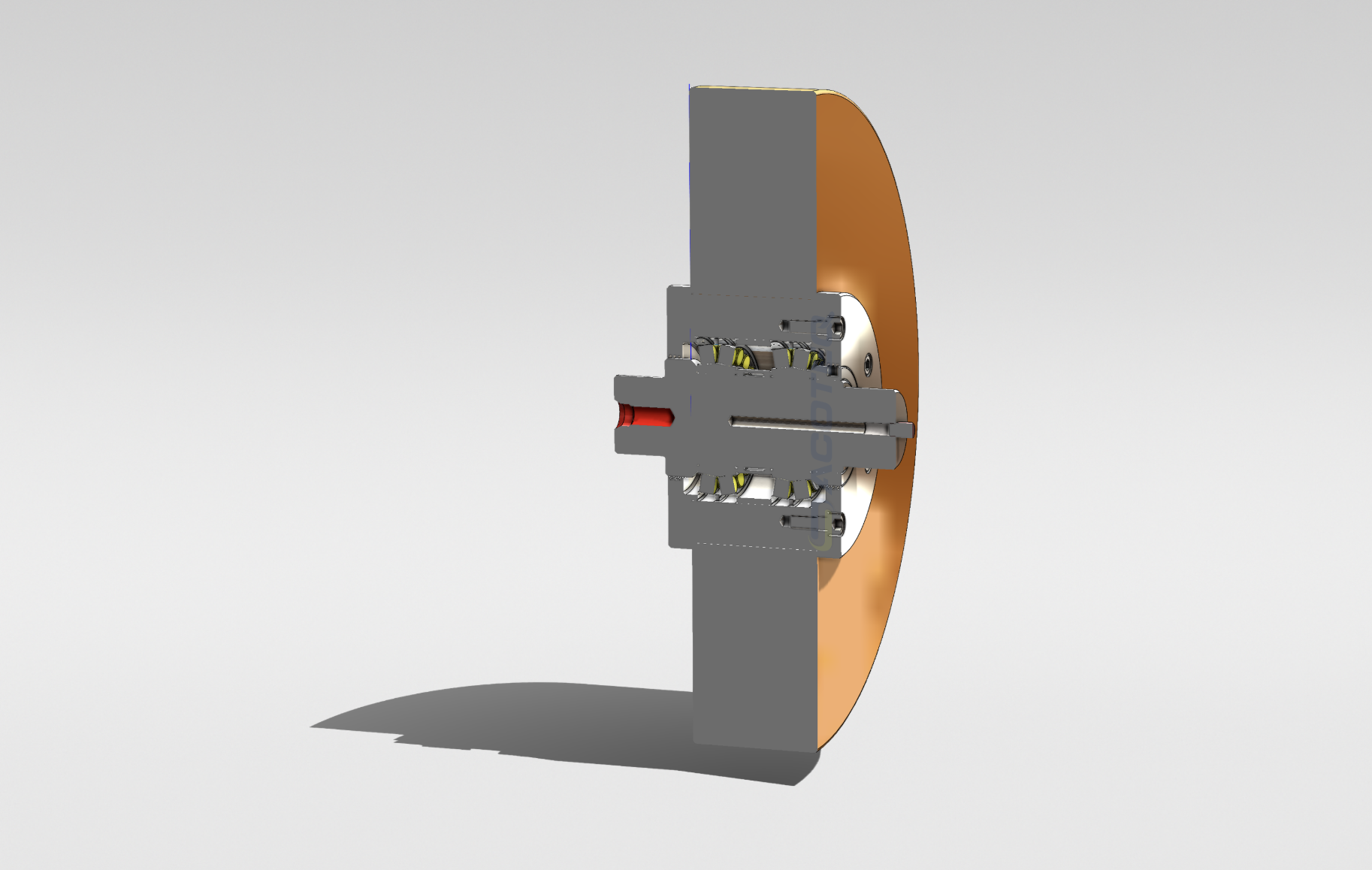

- Selection of Bearing System: An excellent roller will fail without the right bearing. We select and dimension bearings based on line speed, load capacity, and the operating environment (humidity, temperature, chemical exposure).

- Roller Support & Under Roller Unit: We design the complete assembly, including roller supports and under-roller units, ensuring structural stability and facilitating future maintenance access.

Technical Service

Our commitment does not end at delivery. We ensure your rollers operate at peak performance throughout their entire lifecycle.

- On-Site Support: Our specialist engineers travel to your plant to perform diagnostics, supervise installation, and conduct fine-tuning of rollers in real-world operation, minimizing downtime.

- Upgrade Old Roller (Refurbishment): Do you have steel cores or old shafts in good condition? We evaluate the feasibility of recovering your metal components and applying GESADUR® technology, significantly reducing costs compared to purchasing entirely new units.

- Upgrade Roller Bearing: We improve the reliability of your current systems by replacing obsolete housings and bearings with modern, low-friction, high-load technologies, extending the service life of the entire assembly.